Single Chamber Orifice Fitting

- Home

- Single Chamber Orifice Fitting

Canalta

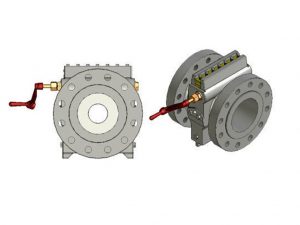

Single Chamber Orifice Fitting

The Canalta Single Chamber Orifice Fitting is designed and constructed to allow for ease of orifice plate replacement or inspection after depressurization.

- All fittings come standard with a documentation package including hydro-test, function test, inner valve seal test, quality control inspection and material test reports.

- Traceability is maintained in accordance with the ISO-9001 Quality Control Program.

- The fittings are manufactured within the guidelines of ASME 16.34 and ASME 16.5.

- When required, radiography, stress relief, ultra-sonic, magnetic particle, and liquid dye penetration tests can be performed with the relevant reports submitted.

Take a closer look at the

Single Chamber Orifice Fittings

Equalizer Valve Assembly

316 SS- Clamping Bar Screw

Material - 4140 CS - Clamping Bar

Mateial - 1018 YZP CS - DC Specification Plate

Material - 316 SS - Operating Wrench

Material - Cast Iron - Flange X Flange Body

Material - A352 LCC - DC Operating Plate

Material - 316 SS - Pinion Gear Assembly

- Flangeneck Body

- Seal Bar

- Drain Plug

- Meter Tap Plug

- Pressure Gauge

- Swivel Blow Out Preventor

- Top Housing

- DBB Needle Valve Assembly

- Equalizer Valve Assembly

- Soft Seat Warning Plate

- Mid Housing

- Flangeneck Body

- Slide Valve Indicator Plate

- Clamping Bar Screw

- Top Housing

- GEAR SHAFT COMPONENTS

- Body Hex Nut

- Bleeder Valve

- Equalizer Valve Assembly

- Grease Gun Assembly

- Integral Flange

- Integral Flange Bolt

- Eccentricity Alignment Plug

Rack and Pinion Gear System

HNBR O-ring Seals

Rack and Pinion Gear System

Single Chamber Orifice Fitting models 8” and larger incorporate a rack and pinion gear system to manage the sizeable weight of large orifice plates and carriers. With this system, plate changing remains quick and easy. These models also feature fully accessible and adjustable eccentricity of the orifice plate from the exterior of the fitting. Tamper-proof sealing is done on request.

Single Chamber Orifice Fitting models 8” and larger incorporate a rack and pinion gear system to manage the sizeable weight of large orifice plates and carriers. With this system, plate changing remains quick and easy. These models also feature fully accessible and adjustable eccentricity of the orifice plate from the exterior of the fitting. Tamper-proof sealing is done on request.HNBR O-ring Seals

All Single Chamber Orifice Fittings come standard with HNBR O-ring seals on the seal bar. This feature provides you with superior sealing capability while eliminating nuisance gasket maintenance and clamping bar screw breakage. The O-rings incorporated are standard shelf sizes and can be supplied in a wide variety of compositions. Gaskets are also available and can be used when preferred or required.

All Single Chamber Orifice Fittings come standard with HNBR O-ring seals on the seal bar. This feature provides you with superior sealing capability while eliminating nuisance gasket maintenance and clamping bar screw breakage. The O-rings incorporated are standard shelf sizes and can be supplied in a wide variety of compositions. Gaskets are also available and can be used when preferred or required.Operations & Maintenance Guide

2 - 6" Single Chamber Orifice Fitting

Looking for assistance? Eager to understand our products better? Dive into our instructional video to discover the ins and outs of operating and maintaining the 2 – 6″ Single Chamber Orifice Fitting by Canalta Flow Measurement.

- Orifice fittings supplied in Canada are built in accordance with the ABSA Quality Control Program and carry a CRN registration number.

- Industry Canada Approval Number AF-0014.

- In compliance with ASME 16.34 and ASME 16.5, ASTM specifications, AGA-3 Latest Edition and ISO-5167.

- SA216 WCB, SA352 LCC or A351 CF8M

- AISI 4130 Carbon Steel, 316 or A351 CF8M Stainless Steel

- 2” through 24”, 150 through 1500 ANSI raised face flange

- 600, 900 and 1500 flanges also available in RTJ face flange

- Flangeneck design (weldneck U/S, flange D/S)

- Flange x Flange

- Weldneck both end

40, 60, 80, 100, 120, 160 and custom sizes

- Seal bar - HNBR O-ring standard, gasket optional

- Orifice plate - Type “K” 2000 Edition formed HNBR seal on a 316 SS retainer ring

- Dual Ring HNBR O-rings standard on a 316 SS retainer ring assembly

- Teflon Snap Seal two-piece virgin Teflon assembly

In conformance with AGA-3 Latest Edition and ISO-5167

In conformance with AGA-3 Latest Edition and ISO-5167

- Two 1/2” NPT per side standard, two 1/2” NPT additional per side optional (TT)

- 2” and 3” fitting sizes center bored to .375” inside diameter

- 4” and larger sizes center bored to .500” inside diameter

- Tolerance +/- 1/64”

- 2” through 6” = 0.562”, 8” through 14” = 0.688”, 16” through 20” = 0.813”

- 24” through 30” = 0.875"

- Shafts are a feature only on fitting sizes 8" and larger

- Left hand mount standard on sizes 8” through 16”

- Dual operation on sizes 20” and larger

- Standard at -20° to 100° F, optional -40° to 1200° F

Vertical or horizontal