Manifold Valves

- Home

- Manifold Valves

Manifold Valves

Canalta's manifold valves bring an innovative design to help maintain the integrity of the bonnet threads by segregating them from the process media. Our valves help to maintain the integrity of the bonnet threads by segregating them from the process media. The seal improves metal-to-metal, bonnet-to-bonnet contact forces while pressures increase and a dual outlet orifice to maximize fluid flow, increasing the pressure limits to 10,000 psi.

- Patent awarded for innovative designs which improve overall use and integrity

- Valves are built for maximum durability and performance and are 100% helium-leak tested for guaranteed reliability.

- Documented and certified tests done by independent sources

- Zinc-nickel plating far outperform the electroless nickel and cobalt plated valves in terms of resistance to corrosion

- WEEE and RoHS compliant

Canalta valves that incorporate this patented design include our 100 Series hard seat mini valves, 800/850 Series bleed valves, all 2-valve block and bleed valves along with 5-valve manifolds.

A significant number of international aerospace and automotive companies have made the switch to zinc-nickel plating for their components over the last decade, so we decided to put this plating to the test for ourselves.

Testing done by an independent lab showed two samples that had been zinc-nickel plated, had no visible corrosion after 1000+ hours in a test chamber being exposed to 5% salt spray (fog). Internal tests yielded the same results after being submerged for 3,500 hours in a 10% salt solution. All carbon steel Canalta needle and manifold valves now utilize this material as standard plating because of these impressive results.

These improvements are ideal for most industrial applications and are becoming increasingly important for outdoor applications. In addition to its excellent corrosions resistance, zinc-nickel plating provides increased deposit hardness, resulting in extended wear resistance.

Manifolds/Stabilizers/Needle Valves

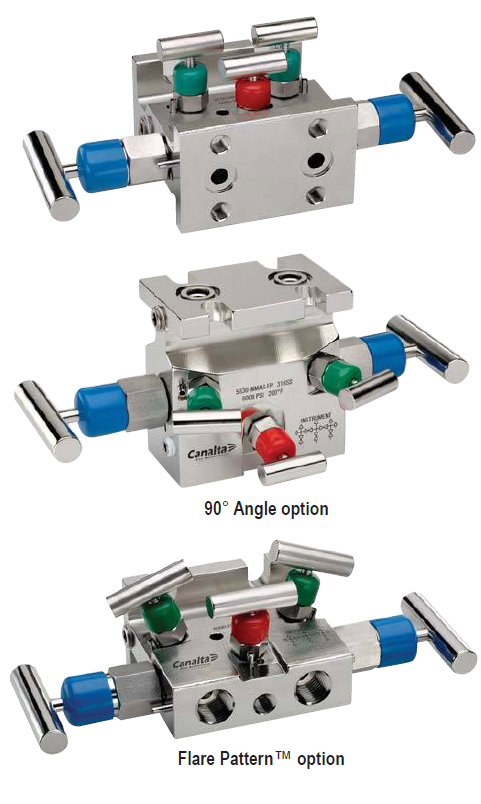

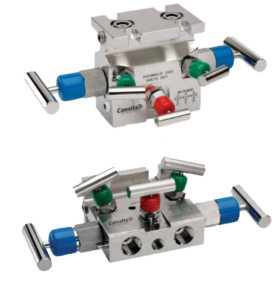

5-Valve Natural Gas Manifold Valve

5-Valve Natural Gas Manifold Valve

- Soft Seat/Tip (0.375)

- Flare Pattern

- Angled option

- Flange x Flange style

- Flange x 1/2″ NPT style

- 1/2″ NPT x 1/2″ NPT style

Manifold Valve Accessories

- Dielectric Kit (single piece design)

- Vertical to Horizontal Adaptor Kit

- Traditional to coplanar spacing adaptor plate

- Stabilizer w/ Integral Block Valve (flange with adaptors included)

- Long/short stabilizers

- Flange adaptors

- Dielectric Kits

Needle Valves w/ T-Style handle

- Male – Male style

- Male – Female style

- Female – Female style