CoFlo Fittings

- Home

- CoFlo Fittings

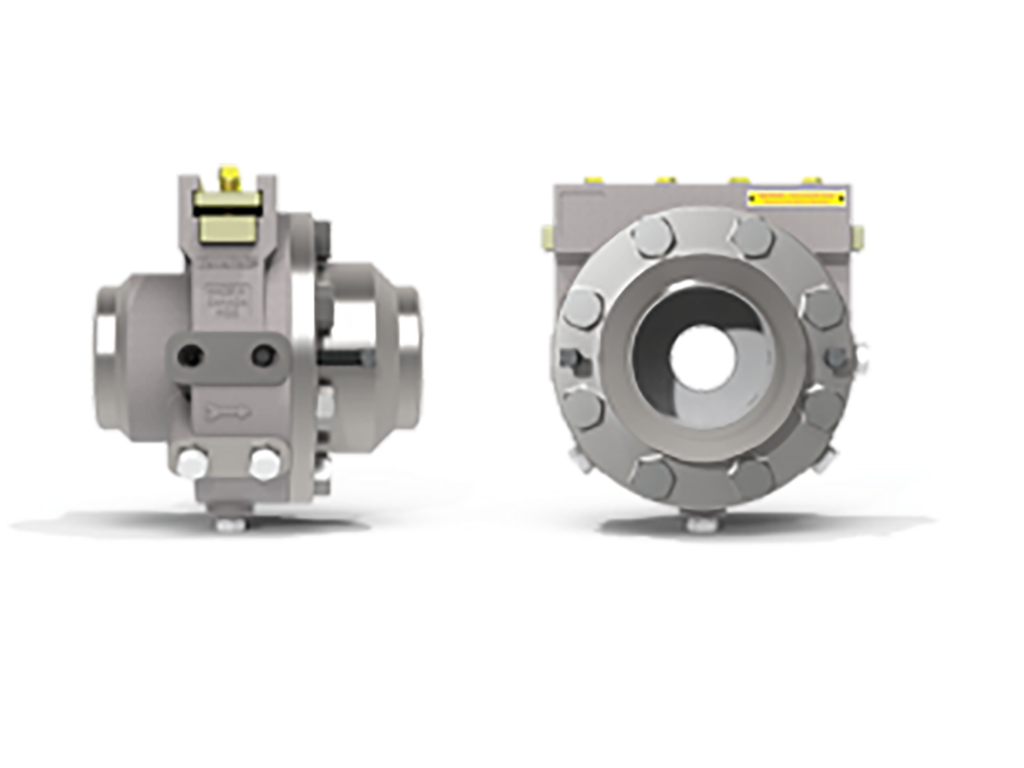

CoFlo Fitting

Our new CoFLo design is a new way of looking at simplistic accurate DP measurement. It offers the same accurate and repeatable measurement qualities that you have come to expect in a standard single-chamber orifice fitting but with the following advantages.

Fabricators and end-users alike from around the globe will see cost savings advantages by utilizing the new innovative design. Not only does it provide a cost advantage over the Standard SC unit, but fabricators will also see cost savings during the design and manufacturing of the complete (end-use) ready meter tube construction.

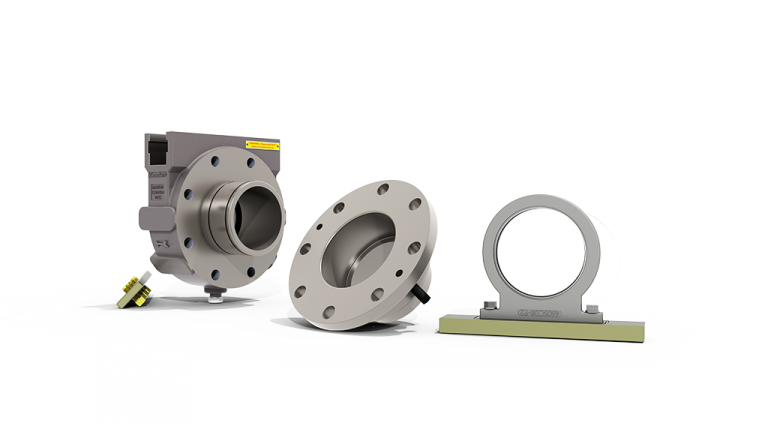

The CoFlo fitting on the downstream portion of the orifice fitting reduces the required number of flanges that goes into a typical (WxF fitting) meter tube build. It eliminates the required or sought-after “companion flange” and the required gasket.

From a manufacturing perspective, it will reduce labor costs by eliminating one extra weld, one extra weld removal, and the risk involved in potential damage during such process.

The CoFlo fitting provides additional value by being the first of its kind to offer a wide array of ANSI class pressure ratings all in one fitting. This new design will allow 150 through 900 ANSI class requirements without further addition.

Available in 2″ through 4″ models, this is Canalta Flow Measurement bringing a new flavor of accurate, repeatable, and dependable measurement solutions to those that believe MEASUREMENT MATTERS.

- – Protection from over-torquing

- – O-Ring sealing

- – Compact for tighter fits

- – Available as fitting only, retrofit or complete AGA-3 or ISO-5167 meter.

- – Flange pressure rating from 150 – 900 ANSI

- – Removes the upstream flange gap

Orifice Fittings

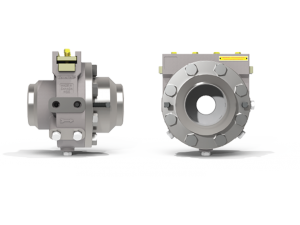

This innovative design is available in the Single Chamber, Dual Chamber, and DBB body styles and comes standard with our Flow Conditioner Housing unit. This provides all with ease of choice and more options to designing needs.

This innovative design is available in the Single Chamber, Dual Chamber, and DBB body styles and comes standard with our Flow Conditioner Housing unit. This provides all with ease of choice and more options to designing needs.

This design allows for the removal of 1 gasket,1 flange, and an entire bolt-up kit on each meter run. This reduction in materials could result in the savings of thousands of dollars to the bottom line.

This design allows for the removal of 1 gasket,1 flange, and an entire bolt-up kit on each meter run. This reduction in materials could result in the savings of thousands of dollars to the bottom line.

This innovative design still comes with the same quality standards and conformity that all Canalta Controls Ltd. fittings come with. A design that can be trusted.

This innovative design still comes with the same quality standards and conformity that all Canalta Controls Ltd. fittings come with. A design that can be trusted.

Download the brochure

Learn more about our CoFlo Fittings by downloading the brochure!

- Orifice fittings supplied in Canada are built in accordance with the ABSA Quality Control Program and carry a CRN registration number.

- Industry Canada Approval Number AF-0014.

- In compliance with ASME 16.34 and ASME 16.5, ASTM specifications, AGA-3 Latest Edition and ISO-5167.

- A216 WCB, A216 WCC, A352 LCC, A358 CF8M, A995 Gr4A, A995 Gr6A, Custom

- AISI 4130 Carbon Steel, 316 or A351 CF8M Stainless Steel

- 2" through 12", 150 through 2500 ANSI raised face flange

- 14" through 16", 150 through 1500 ANSI raised face flange

- 18" through 30", 150 through 600 ANSI raised face flange

- 600, 900 and 1500 flanges also available in RTJ face flange

- Flangeneck design (weldneck U/S, flange D/S)

- Flange x Integral Flange

- Weldneck X Integral Flange

40, 60, 80, 100, 120, 160 and custom sizes

- Seal bar - HNBR O-ring standard, gasket optional

- Shafts - Teflon packing standard, HNBR O-ring optional

- Inner valve - Grease seal standard, HNBR O-ring optional

- Orifice plate - Type “K” 2000 Edition formed HNBR seal on a 316 SS retainer ring

- Dual Ring HNBR O-rings standard on a 316 SS retainer ring assembly

- Teflon Snap Seal two-piece virgin Teflon assembly

In conformance with AGA-3 and ISO-5167 Latest Edition

In conformance with AGA-3 and ISO-5167 Latest Edition

- Two 1/2” NPT per side standard, two 1/2” NPT additional per side optional (TT)

- 2” and 3” fitting sizes center bored to .375” inside diameter

- 4” and larger sizes center bored to .500” inside diameter

- Tolerance +/- 1/64”

- 2” through 6” = 0.562”, 8” through 14” = 0.688”, 16” through 20” = 0.813”

- 24” through 30” = 0.875"

- Left hand mount standard on sizes 2” through 14” (150-1500 ANSI)

- Dual operation on sizes 16” and larger, or 2500 ANSI

- Standard at -20° to 100° F, optional -40° to 1200° F

Vertical or horizontal