Dual Chamber Orifice Fitting

- Home

- Dual Chamber Orifice Fitting

Dual Chamber Orifice Fitting

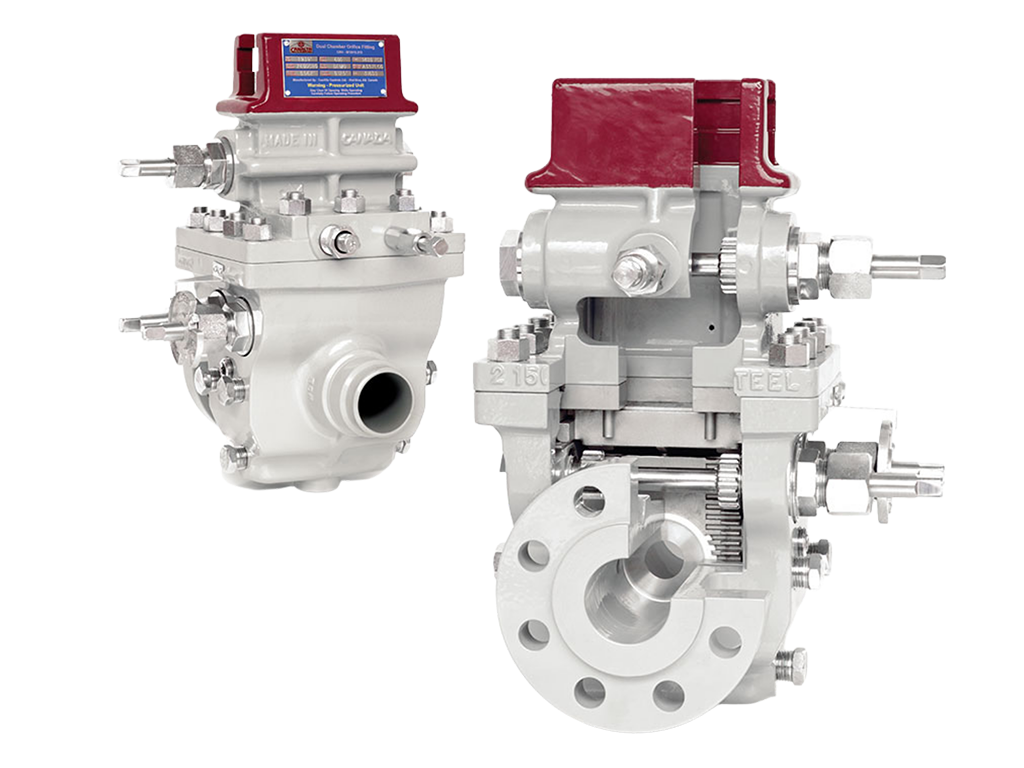

The Canalta Dual Chamber Orifice Fitting allows for accurate flow measurements, orifice plate inspection and changing without breaking apart or depressurizing the flow line.

- All fittings come standard with a documentation package including hydro-test, function test, inner valve seal test, quality control inspection and material test reports.

- Traceability is maintained in accordance with the ISO-9001 Quality Control Program.

- The fittings are manufactured within the guidelines of ASME 16.34 and ASME 16.5.

- When required, radiography, stress relief, ultra-sonic, magnetic particle, and liquid dye penetration tests can be performed with the relevant reports submitted.

Dual Chamber Orifice Fittings

Equalizer Valve Assembly

316 SS- Clamping Bar Screw

Material - 4140 CS - Clamping Bar

Mateial - 1018 YZP CS - DC Specification Plate

Material - 316 SS - Operating Wrench

Material - Cast Iron - Flange X Flange Body

Material - A352 LCC - DC Operating Plate

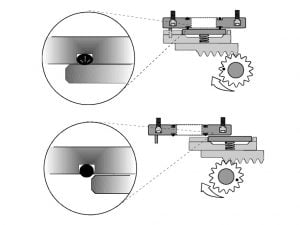

Material - 316 SS - Pinion Gear Assembly

- Flangeneck Body

- Seal Bar

- Drain Plug

- Meter Tap Plug

- Pressure Gauge

- Swivel Blow Out Preventor

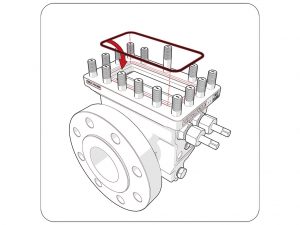

- Top Housing

- DBB Needle Valve Assembly

- Equalizer Valve Assembly

- Soft Seat Warning Plate

- Mid Housing

- Flangeneck Body

- Slide Valve Indicator Plate

- Clamping Bar Screw

- Top Housing

- GEAR SHAFT COMPONENTS

- Body Hex Nut

- Bleeder Valve

- Equalizer Valve Assembly

- Grease Gun Assembly

- Integral Flange

- Integral Flange Bolt

- Eccentricity Alignment Plug

Parts matter, whatever your service environment. Our standard 316SS stainless steel internals offers superior corrosion protection and resistance to sulfide or hydrogen-induced cracking, providing reliability and performance over a long service life. These parts conform to NACE MR0175 / ISO 15156:2015 specifications. For highly corrosive applications, such as wet H2S service, Duplex or Super Duplex steel internals are available to protect against general and localized corrosion.

Parts matter, whatever your service environment. Our standard 316SS stainless steel internals offers superior corrosion protection and resistance to sulfide or hydrogen-induced cracking, providing reliability and performance over a long service life. These parts conform to NACE MR0175 / ISO 15156:2015 specifications. For highly corrosive applications, such as wet H2S service, Duplex or Super Duplex steel internals are available to protect against general and localized corrosion.

Canalta has endeavored to ensure that our parts and accessories offerings are interchangeable with the current industry standard orifice fitting brand, making Canalta Orifice Fitting internals suitable for re-builds and re-works of our competitors’ product lines.

HNBR O-ring Seals on both the body and seal bar come standard with all Canalta Dual Chamber Orifice Fittings. This feature eliminates nuisance gasket maintenance and clamping bar screw breakage, while providing superior sealing capability. The O-rings incorporated are standard shelf sizes and can be supplied in a wide variety of compositions. Gaskets are also available and can be used when preferred or required.

The Soft Seat Valve Seal is available for all dual chamber models. Particularly suited to low pressure applications, this unique design enables a bubble-tight seal between the upper and lower chambers without the need for frequent lubrication. The specially machined seal channel helps prevent O-ring dislocation, and the O-ring seals incorporated are available in a wide variety of compositions.

Dual Chamber Orifice Fitting

Interested in getting to know our products better? Take a look at our instructional video to get a feel for how to use and maintain the Dual Chamber Orifice Fitting by Canalta Flow Measurement.

- Orifice fittings supplied in Canada are built in accordance with the ABSA Quality Control Program and carry a CRN registration number.

- Industry Canada Approval Number AF-0014.

- In compliance with ASME 16.34 and ASME 16.5, ASTM specifications, AGA-3 Latest Edition and ISO-5167.

- A216 WCB, A216 WCC, A352 LCC, A358 CF8M, A995 Gr4A, A995 Gr6A, Custom

- AISI 4130 Carbon Steel, 316 or A351 CF8M Stainless Steel

- 2" through 12", 150 through 2500 ANSI raised face flange

- 14" through 16", 150 through 1500 ANSI raised face flange

- 18" through 30", 150 through 600 ANSI raised face flange

- 600, 900 and 1500 flanges also available in RTJ face flange

- Flangeneck design (weldneck U/S, flange D/S)

- Flange x Flange

- Weldneck both end

40, 60, 80, 100, 120, 160 and custom sizes

- Seal bar - HNBR O-ring standard, gasket optional

- Shafts - Teflon packing standard, HNBR O-ring optional

- Inner valve - Grease seal standard, HNBR O-ring optional

- Orifice plate - Type “K” 2000 Edition formed HNBR seal on a 316 SS retainer ring

- Dual Ring HNBR O-rings standard on a 316 SS retainer ring assembly

- Teflon Snap Seal two-piece virgin Teflon assembly

In conformance with AGA-3 Latest Edition and ISO-5167

In conformance with AGA-3 Latest Edition and ISO-5167

- Two 1/2” NPT per side standard, two 1/2” NPT additional per side optional (TT)

- 2” and 3” fitting sizes center bored to .375” inside diameter

- 4” and larger sizes center bored to .500” inside diameter

- Tolerance +/- 1/64”

- 2” through 6” = 0.562”, 8” through 14” = 0.688”, 16” through 20” = 0.813”

- 24” through 30” = 0.875"

- Offering dual, right or left handed shafts from 2" through 32"

- Standard at -20° to 100° F, optional -40° to 1200° F

Vertical or horizontal